Torbar averaging pitot tube

Dp flow probe complete with integrated manifold The Torbar flowmeter is a multiport self averaging flow meter with a design based on the classical pitot tube concept of fluid flow measurement. More details: Since the introduction of PLATON Torbar in 1985, thousands have been installed into a wide variety of …

Mass TriBar averaging pitot tube

Pressure and temperature compensated flow measurement The Torbar Mass Tribar is an insertion flowmeter comprising an integral valve manifold, a Pt100 temperature element and a multivariable flow transmitter. More details: The Mass Tribar measures pressure, temperature and differential pressure directly from the Torbar and computes the compensated mass flow within …

Platon FloBar averaging pitot tube

Platon FloBar averaging pitot tube FloBar tubes contain no moving parts. Standard models are manufactured from stainless steel, though alternative material requirements are readily accommodated. More details: Process connection options range from resealable compression fittings, through fixed flanges to valved hot tap variants, making installation a straightforward operation. Local …

Platon SGUV – AIR series

Platon SGUV – AIR series Shunt orifice Flowmeters are direct reading flow measurement systems for clean liquids and gases in pipes from 1 1/4″ to 24″ diameter. More details: By introducing a standard sharp edge orifice plate between flanges on the line, a proportion of the main flow is …

Platon SGUV – Water series

Platon SGUV – Water series Shunt orifice Flowmeters are direct reading flow measurement systems for clean liquids and gases in pipes from 1 1/4″ to 24″ diameter. More details: By introducing a standard sharp edge orifice plate between flanges on the line, a proportion of the main flow is …

Orifice plates

Orifice plates Tab Handled Slip Orifice Plates offer an economical method of generating a DP in pipes for a large range of liquids and gases. More details: Manufactured to suit your process conditions and DP requirements using BS 1042/lSO 5167 calculations, or to dimensions supplied. Orifice carriers, weld neck …

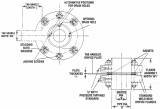

Integral Orifice carriersIntegral Orifice carriers

Integral Orifice carriers In some applications, it is difficult to provide the necessary pressure tappings onsite in the pipework. In these instances, it is advisable to use an orifice carrier. The pressure tappings are provided as an integral part of the carrier and are normally supplied as flange tapped for …

WN orifice plates

WN orifice plates Weld neck Orifice Flange Assemblies include integral pressure tappings as part of the mounting flanges. They are ideally suited to some steam flow applications where the whole assembly is butt welded directly into the line, the flanges being permanently fixed. The orifice plate may be removed for inspection …